Energy Management

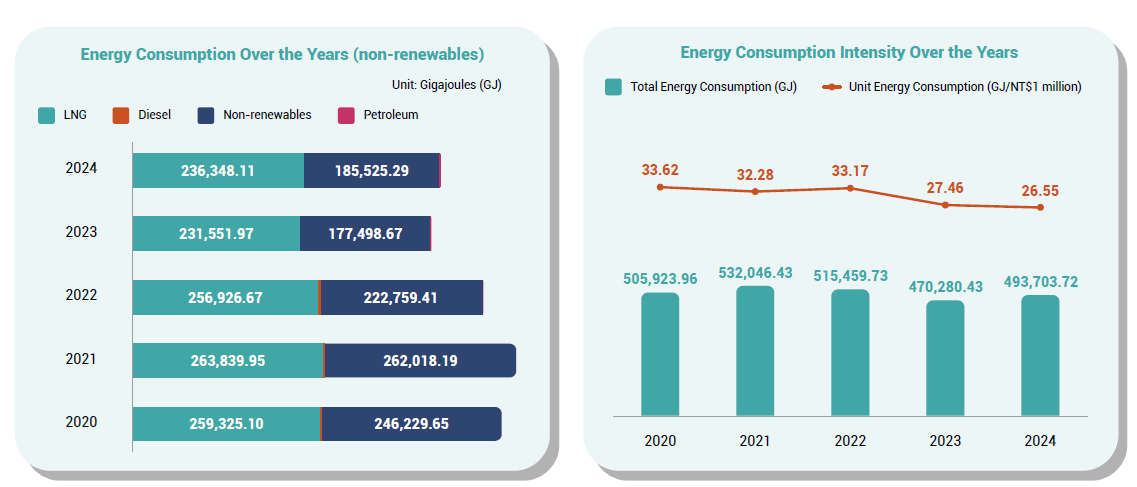

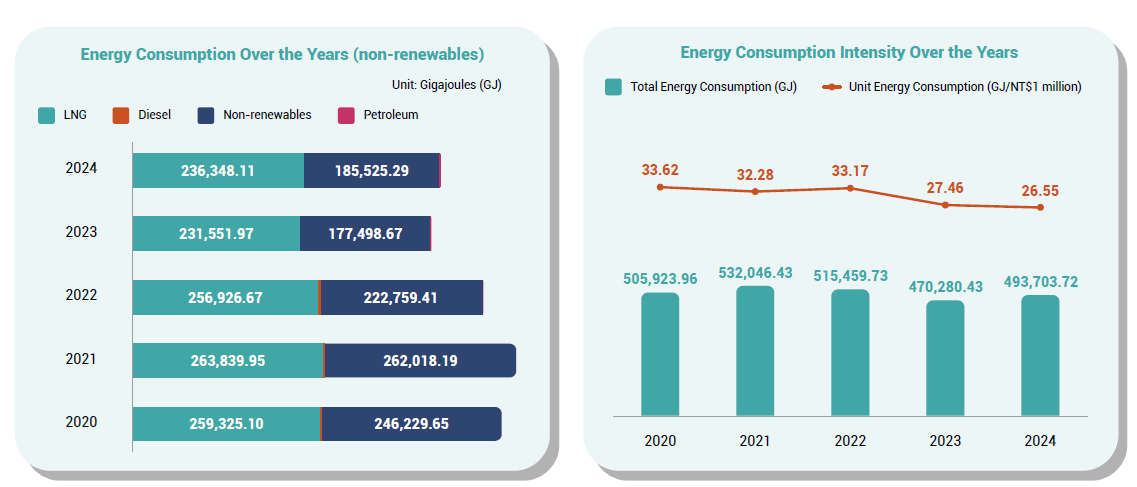

In 2024, the main sources of energy used by BenQ Materials were natural gas and purchased non-renewable electricity, followed by diesel. The total energy consumption in 2024 included 6.2735 million cubic meters of natural gas, 68.8586 million kWh of electricity (including both non-renewable and renewable electricity), 10.9 thousand liters of gasoline, and 5.8 thousand liters of diesel. This equates to a total energy consumption of 497,266.58 GJ, representing an increase of 26,986.14 GJ or 5.74% compared to 2023.

Using revenue as the denominator, the 2024 energy intensity (defined as energy consumption per NT$1 million in revenue) was 26.74 GJ/million NT$, reflecting a decrease of 0.71 GJ/million NT$ or 2.60% compared to 2023.

Note 1: The 2024 disclosure scope for energy management includes the following operational sites: BenQ Materials Headquarters, Taoyuan Plant, Lungke Plant, Yungkang Plant, Suzhou Plant, Wuhu Plant, Hailu Plant, BMC (No. 28), BMM, and DTB.

Note 2: Energy consumption data from 2021 to 2024 has been updated. Data for subsidiaries (Web-Pro, Cenefom, and Jin Jie) is not included in the current disclosure and is expected to be incorporated in 2025 upon completion of third-party verification.

Energy Consumption Intensity Over the Years and Energy Consumption Over the Years (non-renewables)

Note 1: The scope of energy management disclosure in 2023 includes the following operational sites: BenQ Materials headquarters, Taoyuan Plant, Longke Plant, Yunke Plant, Suzhou Plant, Wuhu Plant, Sigma Medical Materials, Hailu Plant, BMC (Dormitory), BMM, and DTB.

Note 2: The energy disclosure data for 2021-2022 has been updated (excluding subsidiaries). The disclosed data does not include subsidiaries (Web-pro, Cenefom, Genejet Biotech ), which are expected to complete third-party verification and be included in the disclosure scope in 2024.

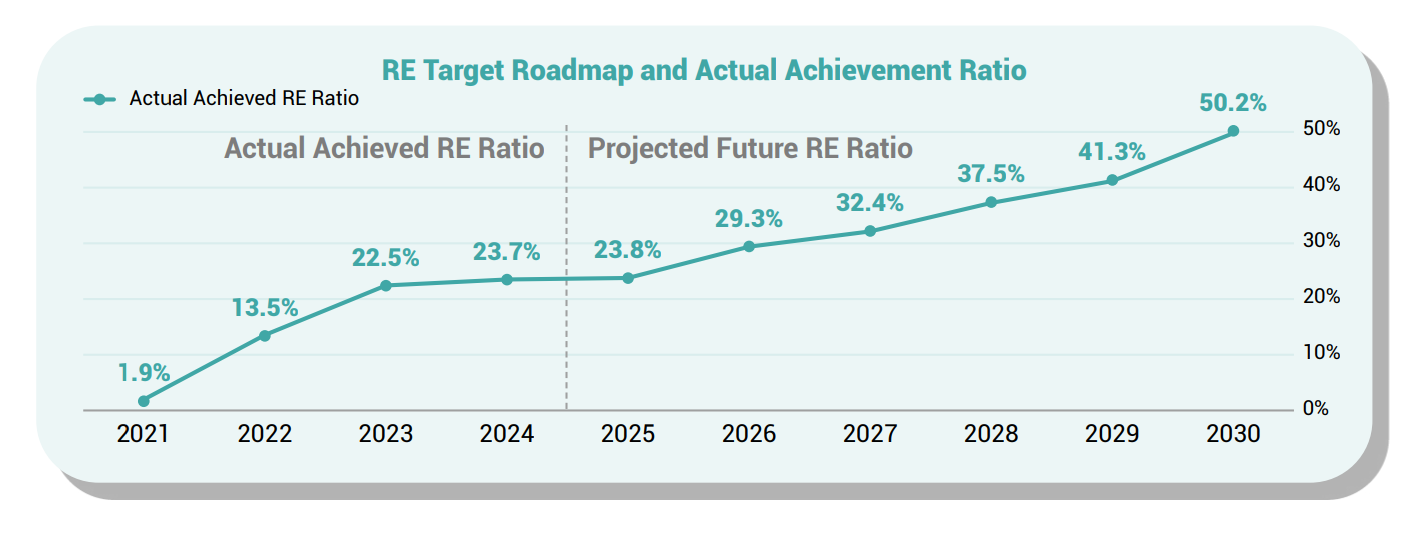

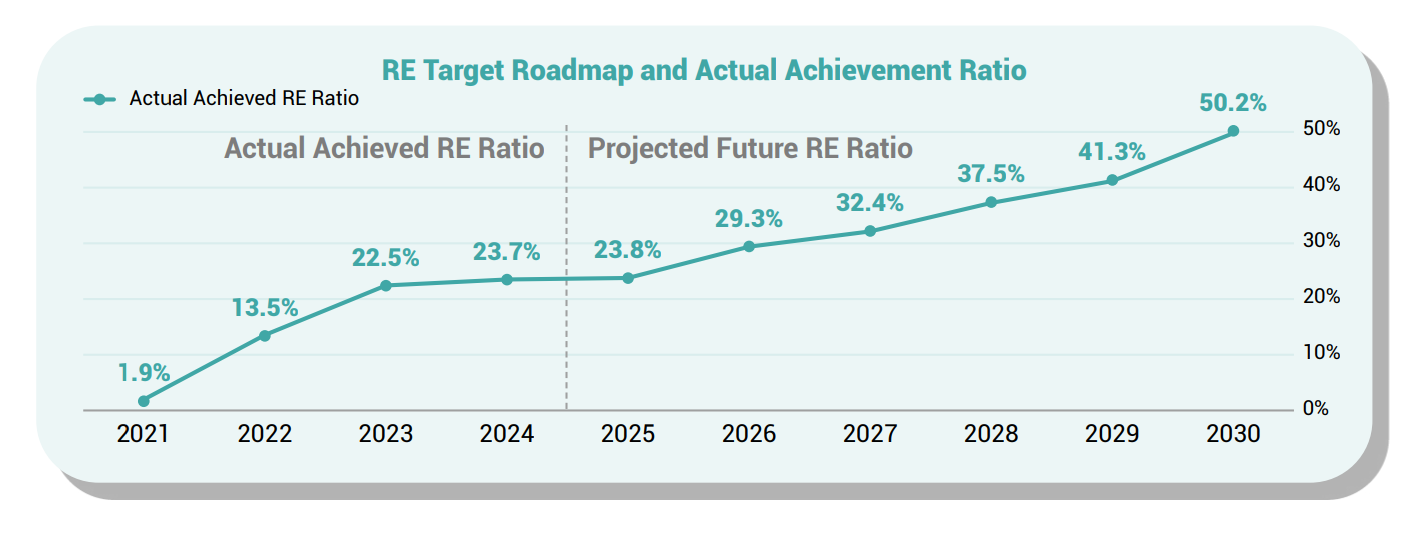

Energy Transition – Use of Renewable Energy

In 2023, BenQ Materials, following the renewable energy strategic goals of the Qisda Group, advanced its original RE100 target timeline from 2050 to 2040 and established a concrete strategic roadmap for achieving RE100. In addition to continuing investments in self-built solar power generation systems for on-site use, the company has actively collaborated with renewable energy electricity providers to gradually expand its procurement of renewable energy, thereby fulfilling its commitments to energy transition and net-zero carbon emissions.

As of 2024, BenQ Materials' total annual renewable energy consumption reached 16,336.3 MWh (equivalent to 16.3363 million kWh), comprising:

• Electricity generation from self-built solar power systems totaling 3,384.3 MWh (338.43 million kWh).

• Procurement of externally purchased renewable energy totaling 2,451.0 MWh (245.10 million kWh).

• Purchase of China-issued GEC/I-REC renewable energy certificates for the China facilities, totaling 10,501.0 MWh (1,050.10 million kWh).

The above renewable energy usage has been utilized to offset the carbon emissions associated with externally purchased electricity across all sites during 2024, as part of the company's voluntary carbon reduction initiatives.

Looking ahead to 2025, the company will continue to increase investments in self-built solar power generation systems for on-site use and further expand external procurement of renewable energy, moving steadily toward achieving the RE100 targets set by the Group and the ESG Sustainability Committee.

Among these efforts, BenQ Materials' textile production facility located in Yunlin (hereinafter referred to as the ''Yunlin Textile Plant'') completed the installation of its solar power generation system in 2024. The system operates under a ''self-generation and selfconsumption'' model, supplying electricity required for the plant's operations. According to statistics, the total electricity consumption of the Yunlin Textile Plant in 2024 amounted to 287,862 kWh, all of which was supplied by the self-installed solar power system, thereby achieving the goal of 100% renewable energy usage for the plant's annual electricity needs.

To enhance transparency and ensure credibility in external disclosures, the Yunlin Textile Plant has also applied for and obtained a total of 804 ''Self-Use Renewable Energy Certificates'' from the Taiwan Renewable Energy Certificate Center (T-REC), corresponding to its actual renewable electricity generation for the year. The certificates fully cover the facility's total annual electricity consumption.

Self-developed renewables

Since 2021, various plants have been constructing solar power generation equipment to supply electricity internally, thereby reducing external electricity purchases and carbon emissions. In 2023, new solar power generation equipment projects were completed and put into use at the Yunke Plant and the Taoyuan Plant. The total annual power generation for all plants reached 2.796 million kWh in 2023. In 2024, the company plans to continue expanding the solar power generation equipment at the Yunke Manufacturing Plant 1. It is estimated that the total power generation for all plants will reach 3.6 million kWh in 2024.

| Year |

Generation capacity (kWh) |

2021

|

1,379,200 |

2022

|

2,530,591 |

2023

|

2,796,485 |

2024

|

3,384,296 |

- Note:Figures were calculated using the electricity carbon emission factor announced by the Bureau of Energy of Taiwan and the Regional Grid Baseline Emission Factor of East China.

Emission Reduction Actions and Outcomes

To mitigate global warming and reduce operational risks associated with climate change, BenQ Materials continuously promotes green manufacturing by implementing energy-saving, emission-reduction, and resource-circulation initiatives aimed at minimizing resource use and consumption. In 2024, a total of 21 electricity-saving projects were implemented, resulting in an annual electricity savings of 1.2623 million kWh and a corresponding reduction of 635.66 metric tons of CO2e emissions. Additionally, six natural gas-saving projects were carried out, achieving an estimated annual reduction of 310.2 thousand cubic meters of natural gas and cutting carbon emissions by 588.49 metric tons of CO2e.

| Item |

Project |

1

|

Energy-Efficient Operation of Nitrogen Generators Upgraded operational controls to improve the energy efficiency of nitrogen generation systems. |

2

|

Replacement of Lighting Fixtures with High-Efficiency Models Phased replacement of traditional lighting with energy-saving LED or high-efficiency fixtures across facilities. |

3

|

Installation of Heat Pumps in MAU Systems at Yunlin Plant II Enhanced energy performance of Make-Up Air Units (MAUs) by adding heat pump systems. |

4

|

Replacement of FFU AC Units with DC Motors / RCU with EC Fans Upgraded from alternating current (AC) motors to direct current (DC) and electronically commutated (EC) fans to increase ventilation energy efficiency. |

5

|

Replacement of Aging Motors with High-Efficiency Permanent Magnet Motors Improved operational efficiency by replacing obsolete motors with energy-efficient permanent magnet types. |

6

|

Installation of High-Efficiency Boilers at Taoyuan Plant Replaced outdated boilers with newly installed high-efficiency energysaving boilers to enhance thermal efficiency. |

Energy efficiency training provided to employees

| Course Title |

Training Hours |

Training Date |

Number of Participants |

| Energy Manager Training |

18 |

2024/11/5 |

2 |