Partnership

BenQ Materials is a leading global display material solution provider, and the company'sproducts include functional film, advanced battery material, professional medical product,personal aesthetic medicine products, waterproof and breathable textiles. Since the product type is diverse, the type of customers also includes enterprises, distributors, and end users. The company is committed to providing satisfactoryproducts and quality service to customers. In addition, the company also values customer exchange, maintains excellent interaction with customers, in order to create maximum value for customers.

2024 supplier engagement programs

Sessions

Completed ESG audits suppliers in 2024

Key suppliers

Green Procurement Amount in 2024

Tens of thousands of NT dollars

Supplier Management

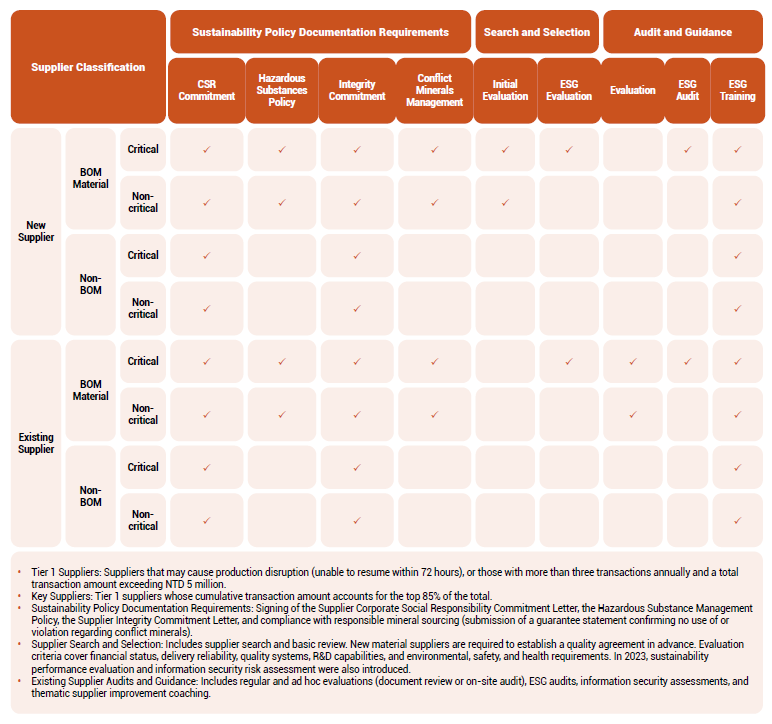

BenQ Materials has established a sustainable supply chain management framework that requires all suppliers to comply with the company’s sustainability policies or related documents. This includes signing the following agreements:

- Supplier Code of Conduct Commitment,

- Declaration of Compliance with Conflict-Free Minerals Requirements, and Hazardous Substances Management Policy.

The company conducts on-site audits, implements corrective actions, and develops supplier capabilities for both new and existing suppliers to mitigate supply chain risks and enhance supplier sustainability performance.

Through a comprehensive sustainable management process, BenQ Materials encourages suppliers to grow together with the company, creating greater shared value and positive impact across the supply chain.

2024 Objective

Completed the First-Stage Key Supplier ESG Audit Target

2024 Outcome

Completed the First-Stage Key Supplier ESG Audit Outcome

| Sustainability Policy Document and Regulation | New Supplier Searching and Evaluation | Existing Supplier Audit and Guidance |

|---|---|---|

|

|

|

Responsible Mineral Sourcing Management

BenQ Materials supports international initiatives on responsible mineral sourcing and conducts due diligence on Conflict Minerals (CM) procurement in accordance with the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals and the framework of the Responsible Minerals Initiative (RMI), as well as customer requirements. The company strictly prohibits the use of conflict minerals originating from the Democratic Republic of the Congo and its neighboring conflict-affected regions to avoid indirectly financing human rights violations, armed violence, or environmental destruction. For more information, refer to the BenQ Materials Raw Material Sourcing Policy.

Selection of Key Suppliers

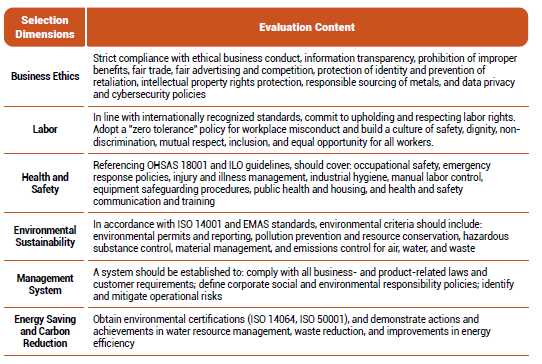

In the process of identifying first-tier key suppliers, BenQ Materials not only considers the number of transactions, transaction amounts, and whether the supplier provides critical materials or technologies, but also evaluates potential negative impacts related to environmental, social, and governance (ESG) aspects of the business. This includes the following criteria:

ESG Auditor

In 2024, BenQ Materials continued conducting ESG audits of suppliers, adopting the Responsible Business Alliance (RBA) framework. Cross-functional teams—including procurement, EHS, and HR—underwent RBA auditor training. Based on supplier transaction values, high-risk suppliers were identified and categorized as mandatory ESG audit targets.

The audit methodology was based on suppliers’ self-assessment scores and ESG/CSR reports, with risk levels classified into four tiers: A, B, C, and D. Suppliers classified as C (medium-high risk) and D (high risk) are deemed high priority for ESG audits. In 2023, four ESG audits were completed, with all suppliers passing the assessments.

Between 2024 and 2026, BenQ Materials plans to complete ESG audits for 14 suppliers identified as medium-high or high risk (originally 15; one was delisted in 2024). Four suppliers were audited in 2024, and the remaining 10 are scheduled for assessment during 2025–2026. Audit targets will be adjusted on a rolling basis according to actual implementation progress to ensure targets are met and to mitigate ESG-related supply chain risks.

Starting in 2025, exemption criteria for ESG audits will be established:

Suppliers who have obtained ISO 14001 (Environmental Management System) certification and publish an ESG/CSR report with disclosed practices and commitments in environmental protection, labor rights, and social contribution may be exempted.

Suppliers who hold third-party ESG certifications such as RBA VAP (Validated Assessment Program), SA8000 (Social Accountability Standard), or reports aligned with the GRI (Global Reporting Initiative) Standards may also qualify for exemption.

Supplier Engagement and Capacity Building

In 2024, BenQ Materials implemented targeted supplier engagement and capacity-building initiatives. The program focused on suppliers identified through ESG audits as having lower self-assessment scores. Key areas of engagement included contractor safety management, energy-saving and carbon reduction case sharing, and ESG trend briefings.

A total of 89 suppliers participated in the program, with 106 participants across all sessions. These initiatives aimed to enhance supplier awareness of sustainability expectations and promote alignment with BenQ Materials’ ESG goals.

Local Purchase

Materials for functional film products (polarizers/optical films/separation membranes/smart window films) are mostly produced by overseas suppliers, with only a few local (Taiwan) suppliers unable to meet BenQ Materials' specifications. As a result, the number and proportion of local suppliers and procurement amounts have been relatively low. However, analyzing procurement amounts over the past five years shows a trend of increasing local procurement. In 2023, the proportion of local procurement in Taiwan was 19.7%, up 2.2% from 17.5% in 2022. BenQ Materials aims to continue collaborating with local suppliers to reduce transportation carbon mileage and promote the local economy.

For materials not related to functional films, the local procurement proportion in Taiwan was 25.0% in 2023, an increase of 11.7% from 13.3% in 2022. The proportion of local suppliers for functional films in China remained stable at 73.9% in 2023, with the local procurement proportion at 89.5%.