Responsible Product

We ensure that the design, manufacturing, quality control, and shipping of our products meet customer expectations. All products comply with relevant safety and labeling regulations in various countries, such as medical devices. We strive for continuous innovation to collaborate with customers in developing innovative and sustainable technology products. Additionally, we aim to reduce the use of organic solvents and minimize waste generation.

All Business Units

100% of new product developments must comply with internal sustainability criteria

Healthcare Products

Waterproof and breathable textiles

e2cycle: Innovative PET Recycling Technology Transforming Electronic Waste into High-Performance Textiles

Green logistics policy

Net-zero emissions" is a global concern for businesses, and achieving net-zero is the ultimate goal. In addition to continuously improving the efficiency of electricity and water usage in our processes, BenQ Materials has implemented low-carbon circular management. This includes promoting low-carbon transportation to reduce carbon emissions caused by transportation, which is a primary focus of our green logistics policy.

Low-carbon Transportation

Low-carbon Transportation

To reduce the carbon footprint associated with logistics operations, BenQ Materials revised its transportation strategy starting in 2023, gradually shifting from air freight to sea freight. In 2024, transportationrelated greenhouse gas (GHG) emissions totaled 3,208 metric tons of CO2e— representing a reduction of 156 metric tons of CO2e compared to 2022, prior to the strategic adjustment. Looking ahead, the company plans to further increase the share of low-carbon transport and adopt carbon intensity– based performance indicators to enhance logistics-related climate performance.

Note: Carbon reduction formula: Number of transports × [Carbon emissions per trip before implementation - Carbon emissions per trip after implementation]

Low-carbon packaging

BenQ Materials continues to implement policies such as ''Recyclable Carton Box Verification,'' ''Reduction of Outbound Shipment Frequency and Air Freight Usage,'' and the promotion of ''Reusable Packaging Boxes'' to encourage and lead customers in adopting sustainable packaging practices.

The company transitioned from single-use corrugated boxes to low-carbon packaging for outbound shipments. By applying design-for-reduction principles and using mono-materials, the packaging volume has been reduced and its environmental impact minimized through reuse.

In 2024, the polarizer production site's outbound shipment data showed that the adoption of recyclable packaging boxes significantly reduced the use of single-use packaging materials. The estimated reduction in packaging-related carbon emissions reached 3 metric tons of CO2e, compared to 2023.

Low-Carbon Recycling Loop

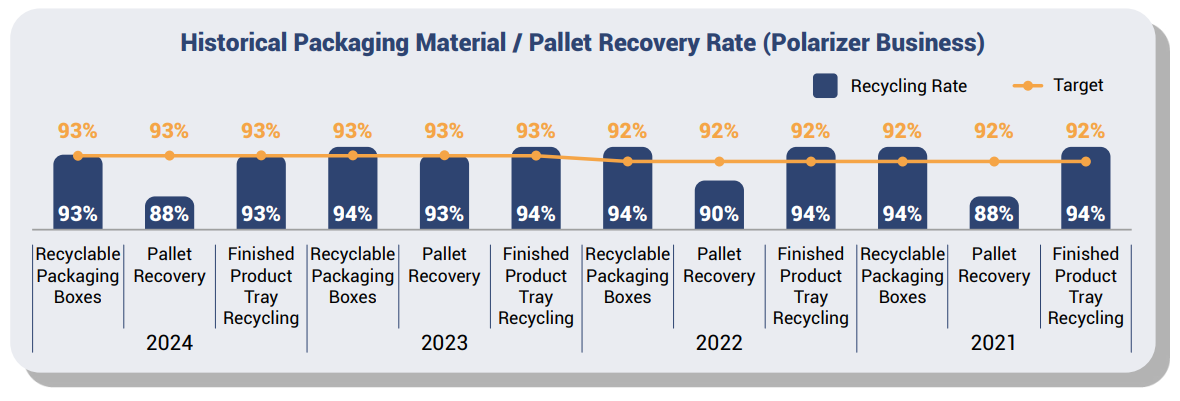

The Display Materials Business adopts recyclable packaging materials and pallets for shipments, incorporating a low-carbon circular management system to track packaging material recovery volumes, recovery rates, and achievement levels. Through a packaging material recovery management mechanism, the company ensures recovery quality and extends the life cycle of packaging materials, thereby reducing material usage and cost, as well as minimizing waste generation.

In 2024, recovery performance included: • Recyclable packaging boxes recovery rate: 93% • Recycled pallets recovery rate: 88% • Recycled product trays recovery rate: 93% • Overall recovery rate: 91%, representing a 2% decrease compared to 2023.

BenQ Materials continues to monitor customers' recovery performance and arranges timely transport for recovered items to reduce the use of single-use packaging. The recovery rate target for 2025 is set at 93%.