Friendly Workplace

Employees are important assets to the company, and our main goal is to create a friendly workplace where employees can work with peace of mind and have opportunities for growth and development. We highly value the voices of our employees and maintain continuous communication through diverse channels. Our continuous efforts aim to create a friendly workplace with a focus on employee well-being.

Average Training Hours for Indirect Employees in 2024

The closure rate of employee complaint channels in 2024

The employee retention rate for outstanding performers in 2024 reached

Workplace Safety

The important operational bases, including Taoyuan Factory, Longke Factory, Yunko Factory, Suzhou Factory, and Wuhu Factory

Occupational Safety and Health Management System

Since 2005, BenQ Materials has obtained certification for the Occupational Health and Safety System (OHSAS 18001). The current management system is based on ISO 45001:2018, established for occupational health and safety management. The certification scope includes the Taoyuan Plant, Longke Plant, Yunke Plant, Suzhou Plant, and Wuhu Plant. Operational activities cover both production and non-production areas, including routine and non-routine tasks, as well as all activities involving external personnel entering BenQ Materials' workplaces. The Taoyuan Plant, Longke Plant, and Yunke Plant have also established CNS 45001, obtaining the TOSHMS Taiwan Occupational Safety and Health Management System certification. By the end of 2023, the number of workers within the certification scope was 2,506 (accounting for 59.92% of the total workforce). Additionally, there were 1,239 non-employee workers, including dispatched personnel, on-site security guards, cleaning staff, company meal staff, and contractors entering the plant for construction, accounting for 29.63% of the total workforce. The total coverage rate of the certification scope was 89.55%, with a total of 3,745 people. Among them, the Hailu Plant and subsidiaries Jingjie, Shuocheng, and Weipu did not conduct ISO 45001 management system certification due to the number of employees being less than 200, totaling 437 people, accounting for 10.45% of the total workforce.

Validity Periods of ISO 45001 Environmental Management System Certifications by Site

| Site | Effective Date | Expiry Date |

| BMC | 2023/09/18 | 2026/10/19 |

| BML | 2022/06/15 | 2025/04/26 |

| BMY | 2025/01/08 | 2028/01/05 |

| BMS | 2023/03/29 | 2026/03/05 |

| BMW | 2024/03/21 | 2027/03/05 |

Occupational Safety and Health Management System

BenQ Materials has established the “Environment, Safety, Health, Energy, and Corporate Social Responsibility Policy" to build a safe, healthy, and sustainable workplace, while implementing a robust occupational health and safety management system. Since 2005, the company has been certified under OHSAS 18001, and the current system has been aligned with ISO 45001:2018. The certification covers routine and non-routine operational activities in both production and non-production areas across Taoyuan, Lungke, Yunlin, Suzhou, and Wuhu sites, including on-site activities by external personnel.

In addition, Taoyuan, Lungke, and Yunlin sites have adopted CNS 45001 and obtained certification under the Taiwan Occupational Safety and Health Management System (TOSHMS).

As of the end of 2024, 2,750 workers were covered under the certification scope, representing 63.67% of the total workforce. An additional 999 non-employee workers—including dispatched personnel, security guards, cleaning staff, catering service providers, and contractors—are also included, bringing the total coverage to 3,749 people, or 86.80% of the workforce.

The remaining 570 personnel at the Hailu site and subsidiaries GENE JET Biotech, Cenefom, and Web-Pro are not included in the ISO 45001 certification due to headcount being below 200, accounting for 13.20% of the total workforce.

Note: The contractor headcount is calculated as the average monthly number of personnel entering the site for outsourced engineering projects and specialized equipment installations.

Hazard Identification and Risk Assessment

In 2024, a total of 11 high-risk mitigation programs were designated for follow-up tracking. These included improvements such as machine guarding enhancements and task procedure optimization. By the end of 2024, 100% of these improvement programs had been completed.

In situations involving changes to products, services, or operational processes that alter the workplace organization, environment, equipment, workforce, or conditions—and may introduce non-routine hazards—employees are required to submit a “Change Management Assessment Form for EHS.” This form triggers a reassessment of hazards and risks associated with the revised activities.

In 2024, 120 such forms were submitted. When the reassessment results indicate unacceptable hazards or high risks and opportunities, corrective measures are implemented following the hierarchy of controls: elimination, substitution, engineering controls, followed by administrative controls such as qualification requirements, warnings, personal protective equipment (PPE), monitoring, and emergency response planning. These measures are continuously improved to reduce risk and ensure workplace safety.

Accident Investigation and Injury Prevention

BenQ Materials has established an incident investigation management procedure aligned with ISO 45001 standards. All workplace incidents are systematically investigated to determine root causes, identify associated hazards, and implement corrective and preventive measures. Follow-up monitoring and care are conducted to support employees’ return-to-work evaluations and ensure sustained improvements.

Employees are encouraged to report unsafe conditions or potential occupational hazards without fear of retaliation. No disciplinary action is taken for such reports. Departments are incentivized to proactively submit environment, health, and safety (EHS) improvement suggestions on a monthly basis. A safety reporting reward mechanism has also been implemented to promote identification of near-miss incidents and potential risks.

During onboarding and regular safety meetings, employees are informed of their right to withdraw from dangerous work. If a worker identifies an immediate danger in the work environment, they are authorized to cease operations and evacuate to a safe area, provided it does not endanger others. The employee must then report the situation to the Emergency Response Center of their site. This will activate internal emergency protocols. Employees exercising their right to refuse unsafe work are protected from dismissal, reassignment, suspension of wages, or any other form of unfair treatment.

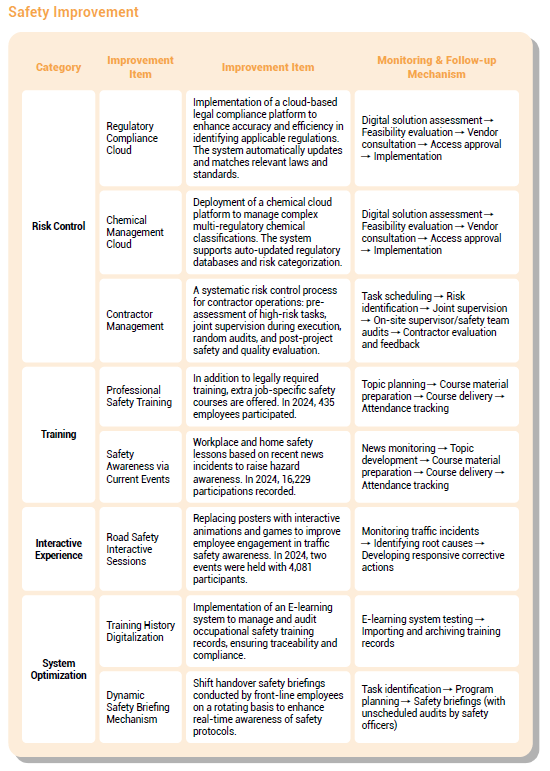

Safety Improvement

Occupational Safety and Health Training

Occupational safety begins with strong safety awareness and emergency preparedness. BenQ Materials prioritizes safety training and awareness across all levels of management and frontline employees to build robust emergency response capabilities and instill safety-first mindsets—proactively reducing unsafe behaviors that may lead to accidents.The annual safety training program includes:

- General Occupational Safety and Health Training for new hires and general employees

- Hazard Communication Training (Hazardous Chemicals Management)

- Machine Safety

- Emergency Response

- Forklift Operation (for loads exceeding one metric ton)

- Crane Operation (for loads between 0.5 and 3 metric tons)

- Lifting Gear Usage

- Boiler Operation

- Occupational Health and Safety Management System Training

To strengthen its occupational health and safety culture, BenQ Materials has adopted a multi-faceted training approach beyond traditional classroom formats. This includes:

- Utilizing digital learning resources from the Occupational Safety and Health Administration (OSHA Taiwan)

- Incorporating external training providers

- Cultivating foreign workers to serve as peer trainers using simplified and localized language

- Hosting external professional safety seminars

These efforts ensure employees are equipped with the knowledge and skills necessary to work safely and contribute to a secure and healthy workplace.

Contractor Occupational Safety Education and Training

To ensure effective contractor safety management, all construction personnel entering BenQ Materials facilities must complete a mandatory safety training program prior to commencing any onsite work. The training covers site-specific safety protocols and regulations for high-risk operations. In 2024, a total of 2,964 contractor participants completed the required safety training.

In addition to contractor training, BenQ Materials has implemented a Contractor Supervision and Oversight System. Under this system, only certified supervisors are authorized to commission outsourced engineering or maintenance projects. This approach ensures both the safety and quality standards of contractor operations are upheld.

In 2024, a total of 276 employees received certified training for contractor supervision.

Note: There were no abnormal incidents involving contractors in 2024.

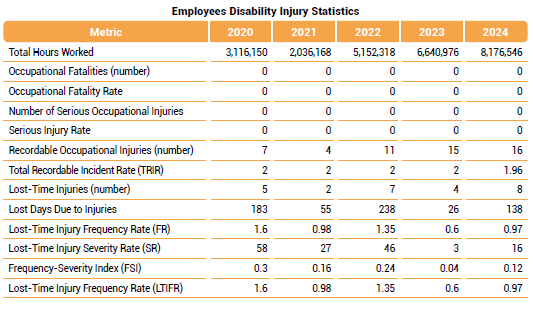

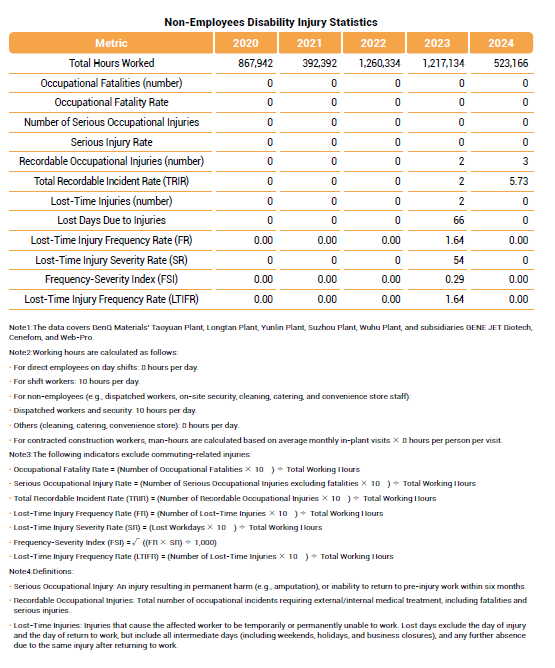

Occupational Injury Statistics

BenQ Materials' occupational injury statistics are disclosed in accordance with the definition of occupational injury under the Occupational Safety and Health Act and the Global Reporting Initiative (GRI) GRI 403-9 occupational injury statistics indicators. In 2023, no fatalities or severe occupational injuries occurred among all workers (employees and non-employees). A total of 17 recordable occupational injuries were reported, mainly involving entanglement hazards, including 6 disabling injuries, resulting in a total of 96 days of lost time due to disability.

The primary types of occupational injuries for employees were entanglement and cutting, caused by inadequate machine safety guards or incomplete standard operating procedures. There were 2 occupational injuries among non-employee workers at BenQ Materials, mainly due to being struck or entangled because of failure to follow standard operating procedures. Safety inspections and improvements for machinery, operating procedures, and environmental safety across the entire plant have been conducted.

2024 Objective

Achieving zero injuries and zero accidents

2024 Outcome

The Overall Injury Index (FSI)

which indicates that the zero disablement injury target has not been achieved